Lithium-ion battery safety: the positives and negatives for workplaces and consumers

The case for lithium batteries

In recent years lithium-ion (Li-ion) batteries have quickly become the most widespread source of portable energy for both commercial and personal use.

Today, Li-ion batteries can be found in:

- Laptops and mobile phones

- Rechargeable power tools

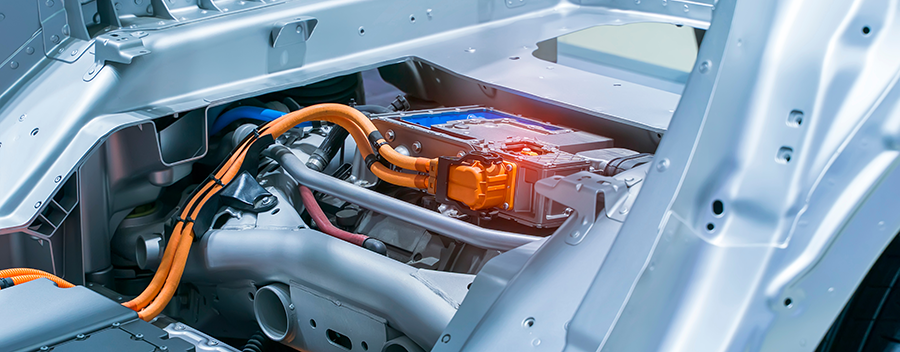

- Electric vehicles

- Electric plant (forklifts, elevating work platforms and earth moving equipment)

- Heavy vehicles (trucks and buses)

- Any other product with a battery that has ‘Lithium’ or some variation of ‘Li’ printed on it.

This increase in popularity is due to the longer lifecycle, quick charging and better power efficiency of Li-ion batteries.

Li-ion batteries have also become important in environmental policy with the ability for Li-ion batteries to store energy from renewable sources helping Australia’s transition to net zero emissions, as well as their long-term use helping Australia’s transition to a circular economy by reducing waste.

However, alongside the increase in prevalence, there has also been an increase in associated incidents, such as fires and explosions, caused by Li-ion batteries. Fire and Rescue NSW reported 318 Li-ion battery fires in NSW for 2024, which was an increase from 272 in 2023, and 165 in 2022. There have also been several fatalities as a direct result of lithium battery fires which has prompted several campaigns and safety alerts to address the risks and requirements around lithium-ion batteries.

In this article, we will look at the potential risks and hazards for consumers and workplaces and how to mitigate them, how to handle a damaged battery, and address any legal obligations for workplaces that use lithium-ion batteries.

Why the risk?

When Li-ion batteries fail they can undergo ‘thermal runaway’. This occurs when the battery overheats uncontrollably and cannot cool down, promoting further chemical reactions and heat. This reaction and the failure of the battery cell can release toxic and flammable vapour and heat in excess of 400°C, leading to fire and/or explosion within minutes.

There are several reasons why a Li-ion battery may fail, including:

- Overheating and exposure to extreme temperatures

- Exposure to moisture

- Using an incorrect charger

- Continuing to charge after the battery is full

- Defective manufacturing

- Physical damage (e.g., if the battery has been dropped, pierced, crushed, or tampered with)

The signs of a damaged or failing battery may include:

- Batteries that are swelling or bulging, leaking, cracked, dented, punctured or crushed

- Overheated batteries that may be releasing vapours or smoke

- Batteries that have gotten wet or exposed to moisture.

Workplace obligations for battery safety

Obligations

Many Australian states are currently in the planning stage for legislation and standards regarding better battery safety. NSW recently passed the Product Lifecycle Responsibility Bill 2025 which includes a product stewardship framework for regulated products that may extend to lithium-ion battery products. Victoria has also presented a draft regulation plan to assess options for mandatory measures to make sure batteries are managed safely throughout their lifecycle.

General requirements

OHS and WHS legislation do not currently explicitly state provisions for lithium-battery safety. Regardless, employers must ensure, so far as is reasonably practicable, to maintain a working environment that is safe and without risks to the health of workers.

This may include, among other things:

- Identifying the hazards associated with Li-ion batteries including, but not limited to, fire, explosion and electrocution

- Controlling the risks

- Developing safe work procedures for the handling and use of Li-ion batteries

- Providing appropriate training and information for all relevant personnel

- Ensuring that appropriate emergency response plans are in place.

Risk control measures

Risk control measures may include:

- Storing batteries in a cool, dry place away from direct sunlight, heat sources, and flammable materials

- Charging equipment using an original or an approved charger and monitoring equipment while charging

- Only purchasing Li-ion products from reliable manufacturers

- Installing ‘Smart Chargers’ that monitor battery status and disconnect if a fault is detected

- Regularly checking the condition of the battery

- Inspecting and maintaining plant powered by Li-ion batteries.

Preventing battery fires at home

For consumers, several incidents have occurred from personal products such as e-bike and e-scooter batteries and many of these incidents stemmed from equipment that was built or engineering by an inexperienced or unqualified person.

When dealing with lithium batteries in the home, other preventative measures you can take to avoid or minimise the risk of a lithium battery fire include:

- Having a working smoke alarm wherever the battery is charged/stored

- Not charging in or near inhabited spaces like bedrooms or living rooms, instead using open areas like a garage or shed that is away from exits

- Charging on hard surfaces that can’t catch fire like concrete floors or tiles.

Safe disposal of batteries

For both workplaces and consumers, it is important that lithium batteries are never disposed of in general household, recycling, or industrial bins where they may be exposed to moisture, heat, or a risk of being crushed.

If the batteries are undamaged, they can be disposed of at your closest collection site or using council e-waste services.

If the batteries are damaged, further steps will need to be taken to dispose of them safely. These may include:

- Isolating damaged batteries from other materials to prevent potential short circuits or further damage

- Storing damaged batteries in suitable contains, such as a fire-resistant bag, and as per manufactures guidelines

- Containers or packages containing damaged batteries being clearly labelled to alert others to potential risks when handling them

- Wearing gloves and protective clothing and equipment when handling damaged batteries or devices

- Seeking guidance by contacting experts or regulatory authorities in your area

- Following regulations, such as the ADG Code , if you do need to transport damaged Li-ion batteries.

It is also important to be aware of the risks related to damaged lithium-ion batteries, including electric shock, secondary fire risks, and exposure to toxic and flammable vapours and substances.

Concluding remarks

While lithium-ion batteries provide better power efficiency and longer lifecycles than other types of batteries and they are important to Australia’s transition to a net zero and the circular economy, they are not without their own risks. The rise in lithium battery fires demonstrates the need for a greater awareness to the risks and the emerging obligations both individuals and workplaces have when it comes to staying safe from the hazards of Li-ion batteries.

References

- ACCC Product Safety Webpage: Lithium-ion batteries guide

- Australian Competition & Consumer Commission Webpage: Consumers urged to use and store lithium-ion batteries safely to prevent deadly fires

- Australian Competition & Consumer Commission Report: Lithium-ion batteries and consumer product safety

- CFA Victoria Webpage: Charging and battery safety

- Department of Fire & Emergency Services Webpage: Lithium-ion batteries

- Fire and Rescue NSW Webpage: E-bike and e-scooter battery safety

- Fire and Rescue NSW Webpage: Alert – E-bike battery at the centre of fatal house fire investigation – Guildford

- Fire and Rescue NSW Webpage: Vision Alert: spate of lithium-ion fires and NSW Government Survey sparks community wakeup call on battery risks – Sydney

- NSW Environment Protection Authority Webpage: NSW leads the charge on mandatory battery safety

- NSW Government Webpage: Lithium-ion battery safety

- NT WorkSafe Webpage: Safe use of lithium-ion batteries at home and in the workplace

- Parliament NSW: Product Lifecycle Responsibility Bill 2025

- Queensland Fire Department Webpage: Lithium-ion battery safety

- SafeWork NSW Webpage: Lithium-ion batteries

- UNSW Newsroom Webpage: Seven things you need to know about lithium-ion battery safety

- WorkSafe Victoria Webpage: Lithium-ion battery fires